LEARN ABOUT THE TRACEABILITY cattle PROCESSES

TRACEABILITY PATH

TRACEABILITY PATH

TRACEABILITY PATH

TRACEABILITY PATH

TRACEABILITY PATH

TRACEABILITY PATH

TRACEABILITY PATH

TRACEABILITY PATH

TRACEABILITY PATH

TRACEABILITY PATH

LEARN ABOUT THE TRACEABILITY POULTRY PROCESSES

Then, the Ecotrace platform publishes the information on the blockchain platform, ensuring that this information is no longer altered.

All the data collected in the process is published on the Ecotrace blockchain platform, attesting to the veracity of the information.

Every primary package, secondary package and pallet has a sequential traceability number, which is always stored on the Ecotrace platform.

TRACEABILITY FROM THE SOURCE

Traceability for the Farmer is about using technology to increase trust in the supply chain. The value of technology lies in its ability to make the supply chain entirely transparent and rich in data of guaranteed origin.

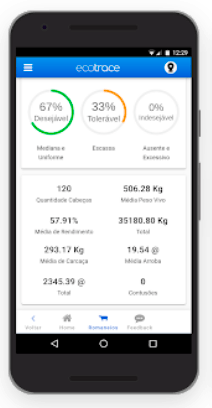

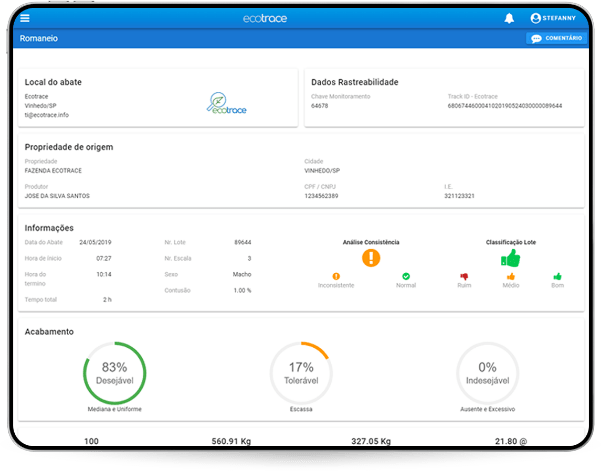

Total control over the yield and quality of each production lot.

Data and evidence of lot processing within the industry.

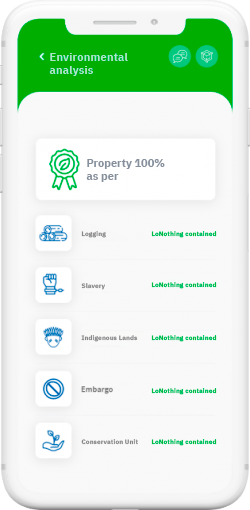

Socio-environmental documentation and analysis always up to date, including required certifications.

Recording of data about inputs such as vaccines, feeds, and other production processes.

TECHNOLOGY ASSISTING THE INDUSTRY

IN THE INDUSTRIAL PROCESS

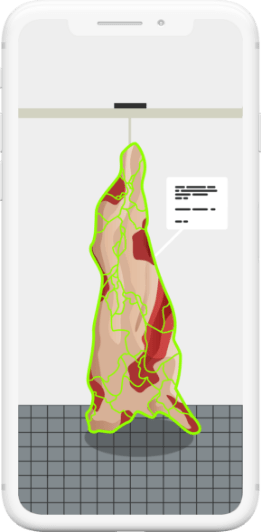

All carcasses are classified with Artificial Intelligence algorithms, using the EcoIA module, thus bringing more transparency to the process. All algorithms are proprietary. 100% auditable system.

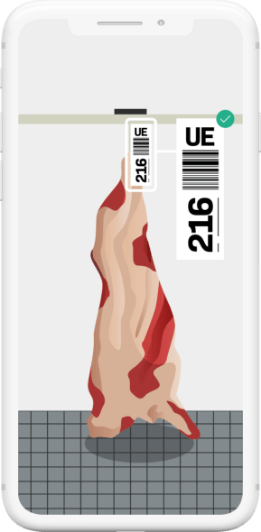

Scanners with cameras for the carcasses

Bruising and Operational Failure Identification

Beef Fat Quality Grading

Photos of all carcasses

ECOTRACE SOLUTIONS

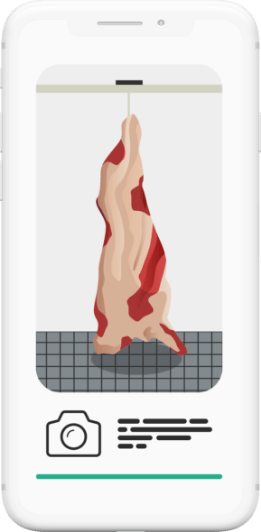

The entire process within the meat processing industry, from the arrival of the animals to the final weighing, is monitored by the Ecotrace platform. This process does NOT replace the current system used in the industry, but works in parallel, through communications using web services between the systems.

Total transparency to the Farmer, returning information for a better analysis of the production process.

-

100% OF THE CARCASSES PHOTOGRAPHED

-

DETAILED TECHNICAL INFORMATION

-

SLAUGHTER DATA CHARTS AND STATISTICS

-

SECURITY AND TRANSPARENCY GUARANTEE OF ORIGIN

-

REAL-TIME SLAUGHTER NOTIFICATIONS

Ecotrace Solutions

FOR GUARANTEE OF ORIGIN

The entire process within the meat processing industry, from the arrival of the animals to the final weighing, is managed by the ecotrace platform, through a set of technologies (IoT modules, cameras, sensors, scales, and scanners) that are installed in the industry, thus securing the entire process.

AUTHORIZED PARTNERS

-

DEFORESTATION TRUSTWORTHY PROPERTY

-

SLAVE LABOR TRUSTWORTHY PROPERTY

-

INDIGENOUS LAND TRUSTWORTHY PROPERTY

-

EMBARGO TRUSTWORTHY PROPERTY

-

CONSERVATION UNITS TRUSTWORTHY PROPERTY

Farmer PORTAL

DON’T WASTE ANY MORE TIME!

Register and get access to all the information from your packing list in the meat packing plants that are Ecotrace partners.

Virtual Assistant

Available

IS YOUR BUSINESS READY

FOR CONSUMER 4.0?

Optimize your customer service. A virtual assistant is available 24 hours a day, with the ability to answer any questions about the product.

HIRE ECOTRACE SOLUTIONS FOR YOUR BUSINESS

Fill in your details and one of our consultants will contact you so that together we can revolutionize the way Brazil does farming.

PORTUGUESE

PORTUGUESE